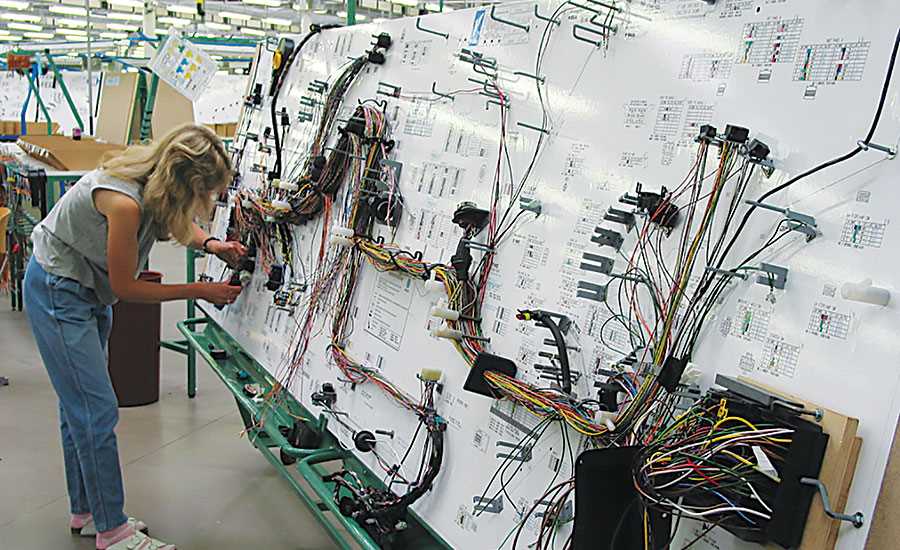

The Case 1840 wiring harness plays a crucial role in ensuring optimal performance and functionality of this versatile piece of equipment. It serves as the central nervous system, connecting various electrical components together and allowing for seamless communication and operation.

Designed specifically for the Case 1840 skid steer, this wiring harness is meticulously engineered to provide reliable and long-lasting service. It is expertly crafted using high-quality materials and advanced manufacturing techniques, ensuring durability and resistance to wear and tear.

With its intricate network of wires, connectors, and terminals, the wiring harness efficiently transmits electrical signals between different components, including the engine, dashboard, lights, and gauges. This enables precise control and monitoring of the skid steer’s operation, enhancing productivity and safety on the job site.

When properly installed and maintained, the Case 1840 wiring harness helps prevent electrical failures, malfunctions, and costly downtime. It minimizes the risk of short circuits, cross-wiring, and loose connections, ensuring uninterrupted power supply and smooth operation of the equipment.

In conclusion, the Case 1840 wiring harness is a vital component that guarantees optimal performance and reliability of the skid steer. Its intricate design and high-quality construction contribute to efficient communication and seamless operation between various electrical components. By investing in a top-quality wiring harness and following proper installation and maintenance procedures, equipment operators can maximize productivity and minimize the risk of potential electrical issues.

Case 1840 Wiring Harness: Everything You Need to Know

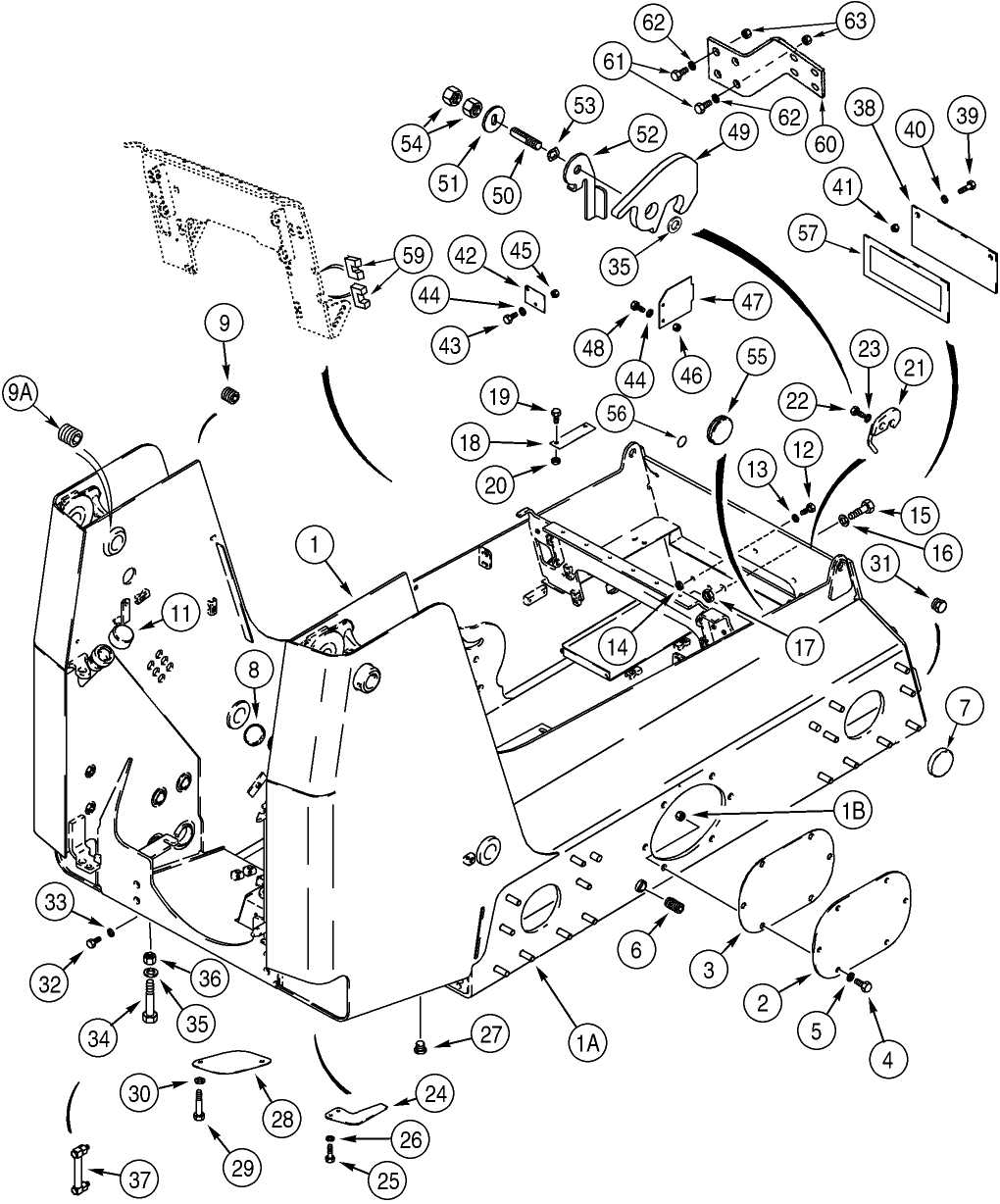

When it comes to the Case 1840 skid steer, having a properly functioning wiring harness is essential for ensuring the smooth operation of the machine. The wiring harness serves as the backbone of the electrical system, connecting various components and allowing them to communicate with each other. Understanding the key aspects of the Case 1840 wiring harness can help you diagnose and troubleshoot any electrical issues that may arise.

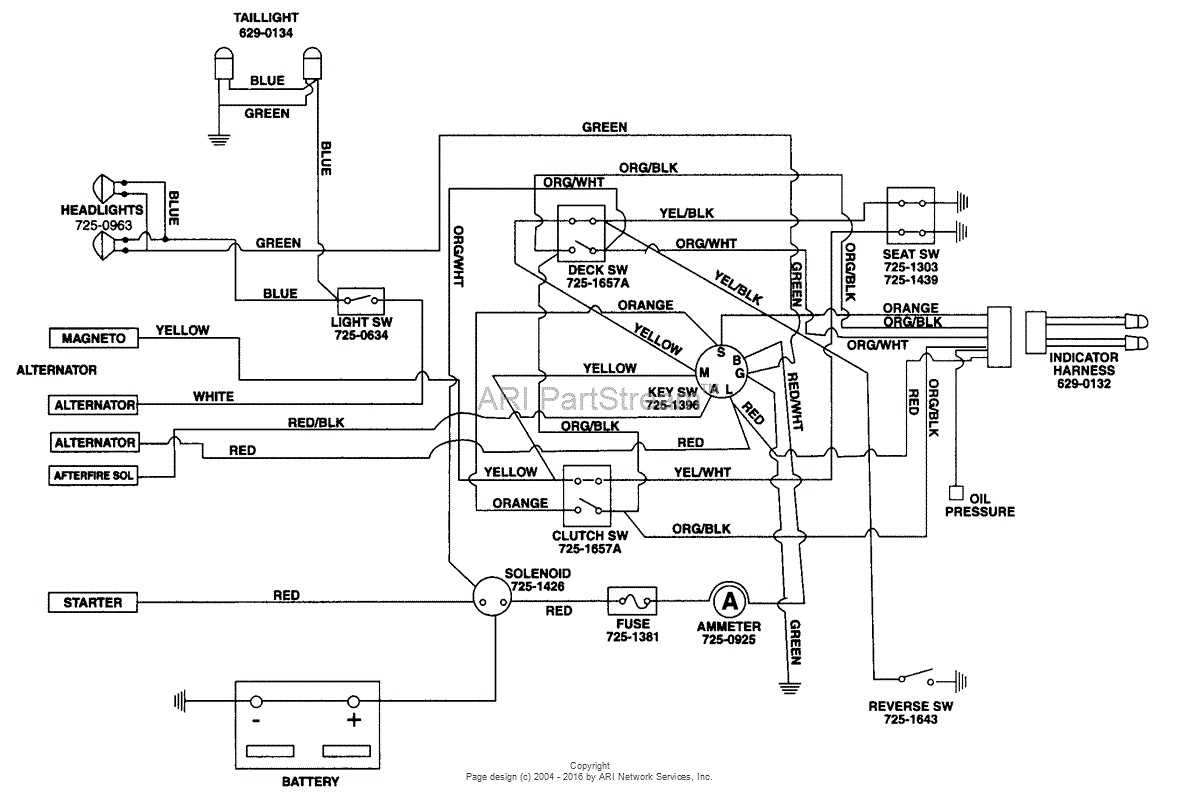

The Case 1840 wiring harness is a complex network of wires, connectors, and terminals that carry electrical signals throughout the skid steer. It consists of multiple sections that are responsible for different functions, such as powering the engine, controlling the hydraulics, and operating the various electrical systems. Each section is color-coded and labeled for easy identification and replacement.

Regular inspection and maintenance of the Case 1840 wiring harness is crucial to prevent any potential problems. Exposure to extreme temperatures, moisture, and vibrations can cause the wires to wear out or become damaged over time. It’s important to check for any signs of fraying, corrosion, or loose connections. Conducting regular electrical tests can also help identify any issues before they escalate.

In case of a malfunctioning wiring harness, it is essential to replace it with a genuine Case 1840 wiring harness. Using a genuine replacement ensures compatibility and reliability, minimizing the risk of any further electrical issues. Additionally, it is crucial to follow the manufacturer’s guidelines and wiring diagrams while replacing the harness to ensure correct installation and functionality.

In conclusion, the Case 1840 wiring harness plays a vital role in the electrical system of the skid steer. Understanding its functions and conducting regular maintenance can help prevent potential problems and ensure the smooth operation of the machine. In case of any issues, it is recommended to consult the manufacturer’s guidelines and use genuine replacement parts for a reliable and long-lasting solution.

Importance of a Proper Wiring Harness

A wiring harness is an essential component in any electrical system, including the Case 1840. It serves as the backbone that connects all the electrical components together, allowing them to communicate and function properly. A proper wiring harness ensures that the electrical system operates efficiently, effectively, and safely.

One of the key reasons why a proper wiring harness is important is because it helps to prevent electrical issues and failures. A quality harness is designed to handle the specific electrical demands of the equipment it is used in, ensuring that the electrical system is protected from short circuits, voltage fluctuations, and other potential problems. Without a proper wiring harness, there is a higher risk of damage to the electrical components, which can lead to costly repairs or even equipment failure.

A proper wiring harness also makes troubleshooting and maintenance easier. With a well-organized and properly labeled harness, it becomes easier to identify and diagnose any electrical issues that may arise. This saves time and effort in troubleshooting, allowing for faster and more efficient repairs.

Furthermore, using a proper wiring harness helps to ensure compliance with safety standards and regulations. The harness is designed to meet specific safety requirements and is made from materials that are resistant to heat, moisture, and other potential hazards. By using a harness that meets these standards, the risk of electrical accidents or malfunctions is reduced, providing a safer working environment for operators and preventing potential damage to the equipment.

In summary, a proper wiring harness is crucial for the performance, safety, and longevity of electrical systems like the Case 1840. It helps to prevent electrical issues, makes troubleshooting and maintenance easier, and ensures compliance with safety standards. Investing in a high-quality harness is a wise decision for any equipment owner or operator.